The creation of SPAM is a combination of quality ingredients and innovative methods that have stood the test of time. This household name has a surprisingly intricate story behind its production. Here are 10 facts about how SPAM is made.

The Core Ingredients

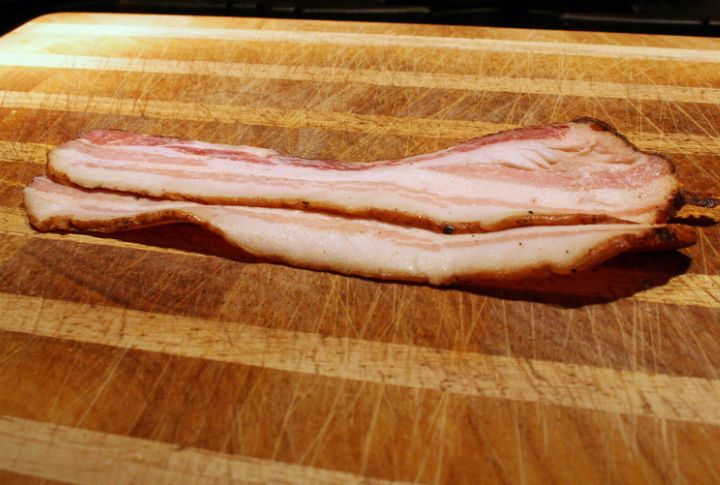

Few realize that pork shoulder and ham, once overlooked cuts, became the backbone of SPAM’s iconic recipe. Introduced during the Great Depression, this combination was chosen for its affordability and flavor.

Salt’s Essential Role

Crystals of salt bring more than taste to SPAM—they are the secret behind its impressive shelf life. As a natural preservative, salt wards off bacteria while amplifying the savory flavor that has kept SPAM a pantry essential for over 80 years.

Water as a Binding Agent

Without water, SPAM’s signature texture would be impossible to achieve. Acting as both a binder and a hydrating element, water ensures the mixture stays evenly distributed. It also locks in moisture, preventing the meat from drying during processing and storage.

Starch That Holds It All Together

Modified potato starch gives SPAM its resilience. The natural thickener stabilizes the meat blend during cooking and cooling so that every slice maintains its structure. Beyond its binding capabilities, the starch also retains moisture.

Sweetness in Balance

A touch of sugar balances the saltiness to create SPAM’s signature flavor profile. A small yet vital addition, it enhances its overall taste. Sugar subtly harmonizes the savory notes without overpowering the natural richness of the pork.

Sodium Nitrite for Safety

Sodium nitrite is a modern safeguard, protecting SPAM from harmful bacteria. This compound, regulated for food safety, ensures long-term preservation and maintains the meat’s vibrant pink hue, which makes every can visually recognizable.

The Art of Blending

Mixing the ingredients for 20 minutes ensures consistency in every can of SPAM. The step distributes the salt, sugar, and starch evenly to guarantee that each bite tastes the same. Precision during this phase is critical to SPAM’s quality control.

Sterilization in the Can

Cooking SPAM inside its can is ingenious. Known as retort cooking, this method sterilizes the contents while preserving flavor and texture. Eliminating bacteria guarantees that SPAM remains safe and delicious for years without refrigeration.

Cooling With Precision

After cooking, the cans are cooled for three hours to ensure stability. The step allows natural gelatin to form, which gives SPAM its characteristic texture. This cooling process protects the product’s integrity and prepares it for labeling and distribution.

A Layer of Gelatin

One of SPAM’s most recognizable features is the gelatin layer that forms during cooking. Derived from the meat’s natural juices, this layer preserves moisture and enhances the texture. It is a hallmark of SPAM’s quality.